There's something incredibly special about taking a piece of wood—something natural and full of character—and turning it into a story. Custom wood engraving does just that, transforming everyday wooden items into one-of-a-kind treasures that feel both timeless and deeply personal.

Using high-tech lasers, we can etch incredibly detailed designs, from a company’s crisp logo to a handwritten message, right onto the wood’s surface. The final product isn’t just an item; it’s a beautiful, durable piece that speaks volumes, perfect for a heartfelt gift or a standout piece of branding.

The Art of Personalized Wood Engraving

Think about it. You can take a plain wooden box and turn it into a family heirloom, passed down for generations. Or you can elevate a standard corporate plaque into a genuine symbol of achievement that someone will actually want to display. That’s the real magic of custom engraving wood.

It’s not just about slapping a design onto a surface. It’s a craft that blends the warm, rustic appeal of wood with the razor-sharp precision of laser technology. The result is a piece where sentiment and identity are literally carved into a beautiful, organic canvas.

Here at 4ULaserWorks, bringing those ideas to life is what we do best. As a BBB Accredited business, we’ve earned our reputation for high-quality engraving and personalized service. We’re even officially licensed with Creighton University, which shows we can handle even the most exacting branding guidelines.

Who Needs Custom Engraving, Anyway?

You’d be surprised how many people can use custom wood engraving to make a lasting impression. It’s an incredibly versatile tool for both business and personal projects. We see it all the time with our clients, which include:

- Corporate Businesses: Looking for sophisticated corporate awards, unforgettable promotional gifts, and branded wooden boxes that don't look like every other company's swag.

- Credit Unions and Banks: These financial institutions often need high-end gifts for top clients or meaningful awards for employee recognition.

- Schools and Sports Teams: From celebrating a championship win to honoring a retiring coach, personalized drinkware and other items are perfect for building team spirit.

- Event Planners: Crafting unique, memorable pieces for weddings, big conferences, and other special occasions is their bread and butter.

When you engrave a piece of wood, you're not just making an object—you're crafting an experience. Every grain pattern is unique, and the way it interacts with the laser means no two pieces will ever be exactly alike.

Here's a quick cheat sheet to break down the key elements of wood engraving.

Wood Engraving Essentials at a Glance

| Aspect | Key Details | Best For |

|---|---|---|

| Technology | CO2 Laser Engravers are used for their precision, speed, and ability to create detailed, high-contrast marks. | Intricate logos, fine text, and detailed photographic reproductions. |

| Wood Types | Woods with a fine, consistent grain like Maple, Cherry, and Alder engrave cleanly and offer beautiful contrast. | Awards, plaques, decorative boxes, and personalized gifts. |

| Design | High-contrast, vector-based images (like .AI or .SVG) produce the sharpest results. Simpler is often better. | Branding, text-based messages, and clear, iconic graphics. |

| Applications | The possibilities are nearly endless, from personal gifts and decor to professional awards and signage. | Corporate branding, event keepsakes, custom furniture accents, and unique art pieces. |

Whether you need a single, deeply personal gift or you're planning a large run of branded items for your company, the process is straightforward and the results speak for themselves.

Let's Talk Technique: How the Magic Happens

When you want a custom piece of wood engraved, you’re not just picking a design—you're choosing a method. Think of it like a painter deciding between a delicate paintbrush and a heavy-duty chisel. Both create art, but the process, the feel, and the final look are worlds apart.

In the custom wood engraving game, there are two main players: laser engraving and rotary engraving. They both get the job done, but they work on completely different principles and each has its own unique superpowers.

The Precision of Laser Engraving

Imagine an artist who paints with a focused beam of light. That's pretty much what laser engraving is. We use a computer-controlled, high-powered CO2 laser to trace a design onto the wood's surface with jaw-dropping accuracy.

Instead of physically cutting into the wood, the laser beam instantly vaporizes a micro-thin layer of the material. This creates a permanent, pristine mark with unbelievable detail. It's a no-contact sport, meaning no blades or bits ever touch the wood, which is how we can achieve those impossibly intricate designs you see on high-end products. This is exactly why it’s the go-to method for everything from complex corporate logos on awards to detailed text on personalized drinkware.

This technology isn't just a niche craft anymore—it's booming. The global wood engraving machine market is on track to hit an estimated $500 million by 2025. That growth is being fueled by a huge demand for personalized products in the corporate, craft, and gift markets. It just goes to show how laser technology has made top-tier engraving more accessible than ever. You can dig deeper into the market's expansion over at Archive Market Research.

Rotary Engraving: The Old-School Craftsman

Now, let's pivot from light beams to good old-fashioned muscle. Rotary engraving is the classic, hands-on approach. It uses a spinning cutting tool—think of a super-precise drill bit—to physically carve the design right out of the wood.

This method has some real power behind it, creating a deep, V-shaped groove in the material. It's like a sculptor's chisel, methodically chipping away wood to reveal the final piece. While it's fantastic for creating bold, deep lettering on certain materials, it can be a bit rough around the edges with wood. The physical force can sometimes cause splintering or "chatter" marks, especially on softer woods or when trying to create a highly detailed design.

Laser engraving vaporizes the wood for a smooth, high-contrast mark. Rotary engraving, on the other hand, physically carves out material, creating a deeper, channeled look.

The Showdown: Laser vs. Rotary

So, which one is right for you? It really boils down to what your project needs. Each technique has its own arena where it shines.

- Detail and Precision: Laser engraving wins this fight, hands down. It can reproduce the finest lines, the tiniest text, and even photo-realistic images with incredible clarity. Rotary engraving just can't compete at that level of intricacy.

- Material Versatility: Lasers are gentle giants. They work beautifully across a huge range of woods, from soft pine to hard oak, without risking damage to the piece. Rotary tools are often a better fit for hard-as-nails materials like metal, where their brute force is actually an advantage.

- Speed and Efficiency: For anything complex, lasers are way faster. The whole process is computer-driven, so it can knock out elaborate patterns quickly and, more importantly, consistently across a hundred items.

- The Final Look: The aesthetics are completely different. A laser gives you that clean, often darkened mark with beautiful contrast. Rotary engraving delivers a deep, traditionally hand-carved appearance.

Here at 4ULaserWorks, we’re all-in on high-quality laser engraving. It delivers the pixel-perfect precision our clients expect, whether we're crafting a sophisticated corporate award or a one-of-a-kind custom wood box. This is the technique that lets us perfectly capture a brand’s logo or a heartfelt personal message. While the core idea of engraving is the same, our methods change for different items. For a peek at another popular application, see our post on how tumblers are engraved. It's this blend of modern tech and skilled craftsmanship that ensures a flawless result, every single time.

How to Choose the Perfect Wood for Engraving

Picking the right wood for a custom engraving project is a lot like a chef choosing the best ingredients. The wood is the foundation, the very canvas for your masterpiece. Its color, grain, and hardness will absolutely define the final look and feel of your design.

Think of it this way: a sharp, high-contrast logo for a corporate award needs a clean, light-colored wood to really pop. But a subtle, elegant monogram on a keepsake box? That might feel far more sophisticated on a darker, richer wood. Getting these details right is the secret to creating wood engravings custom tailored to your vision.

At 4ULaserWorks, we walk our clients—everyone from credit unions and schools to event planners—through these choices every day. It's our job to make sure the material and the design are a perfect match for a stunning result.

Understanding Wood Personalities

Every piece of wood has its own personality. Some are loud and expressive with wild grain patterns, while others are quiet and refined. Learning to spot these traits will help you pick the right material for any project, whether it's a batch of promotional gifts or a one-of-a-kind keepsake.

-

Light Woods for High Contrast: Species like Maple, Alder, and Birch are the rockstars of the engraving world. Their pale color and smooth grain create a dark, crisp mark when the laser hits them. This fantastic contrast is perfect for detailed logos, sharp text, or any design that needs to be crystal clear.

-

Dark Woods for Subtle Elegance: Walnut and Cherry offer a completely different vibe. When engraved, the mark is usually just a few shades darker than the wood itself, creating a subtle, tone-on-tone effect. This whispers quiet luxury, making it ideal for high-end corporate gifts, commemorative plaques, and sophisticated home decor.

-

Grainy Woods for Rustic Charm: Woods like Oak and Hickory have bold, in-your-face grain patterns. This can add a ton of character, but it can also fight with very fine, detailed designs. These woods are at their best with big, simple engravings where the wood's natural texture is part of the charm.

A simple rule of thumb for wood engravings custom projects is this: the less busy the wood grain, the more intricate your design can be. A smooth canvas lets the finest details shine without distraction.

Wood Comparison for Custom Engraving Projects

To make it even clearer, let's break down some of the most popular choices. This table compares common woods based on their core characteristics to help you zero in on the perfect material for your specific needs.

| Wood Type | Hardness | Engraving Contrast | Best Use Cases |

|---|---|---|---|

| Maple | High | Excellent (Dark) | High-end gifts, detailed photos, corporate awards |

| Alder | Medium-Low | Excellent (Dark) | Coasters, plaques, name badges, signs |

| Cherry | Medium | Good (Subtle) | Keepsake boxes, furniture, high-end decorative items |

| Walnut | High | Fair (Subtle) | Executive gifts, plaques, gun stocks, luxury items |

| Oak | High | Good (Varies) | Rustic signs, bold logos, furniture, charcuterie boards |

| Pine | Low | Fair (Inconsistent) | Hobbyist projects, rustic decor, budget-friendly signs |

As you can see, a hard wood like Maple gives you incredible precision, while something softer like Alder provides amazing contrast at a great price point. It’s all about matching the wood’s personality to your project's goals.

Key Factors to Consider

Beyond color and grain, a couple of other things will impact the final result. A wood's hardness, for instance, changes how it reacts to the laser. Softer woods like Pine engrave deep and fast, but the edges might not be perfectly sharp. Hardwoods like Maple, on the other hand, produce incredibly fine, clean lines.

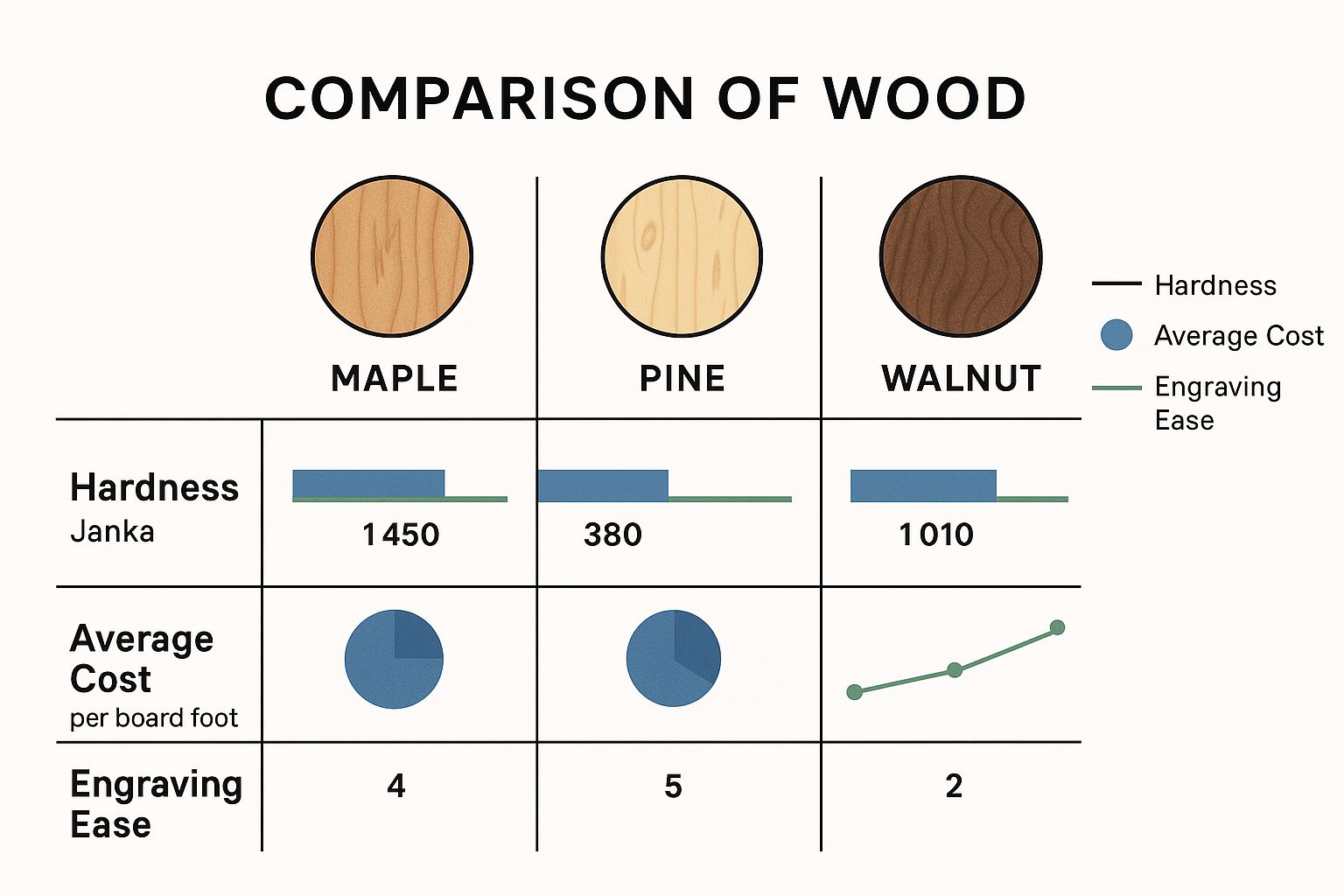

This handy chart gives you a quick visual on how three popular choices stack up.

It’s pretty clear why Maple is a go-to for premium projects that need both durability and precision, while Pine is a solid choice when the budget is tight and the design isn't too complex.

Real-World Applications and Examples

So how does this all play out in the real world?

Let’s say you’re an event planner organizing a corporate retreat. You might choose Alder for the name badges. Why? It's lightweight, easy on the budget, and produces super sharp text that's easy to read from a distance.

Now, picture a totally different scenario: a custom wood box for a high-end client gift. A gorgeous Walnut box with a subtly engraved logo just screams quality and permanence. The rich color and elegant finish make the whole package feel important. This classic appeal is also perfect for things like bespoke presentation boxes, a concept we explore in our guide to customizing whiskey decanter sets.

Ultimately, picking the perfect wood is a balancing act between your aesthetic goals, your design's practical needs, and your budget. Armed with a little knowledge, you can confidently choose a material that not only looks incredible but truly tells the story you want your engraved piece to tell.

Bringing Your Custom Engraving Design to Life

This is where the magic really happens. That brilliant idea floating around in your head starts its journey from a file on a screen to a beautiful, tangible piece of art you can hold in your hands. But getting a design to translate perfectly onto wood is more than just having a cool concept; it's about understanding how that design will dance with the laser and interact with the wood's unique canvas.

Getting the design dialed in from the very beginning is the secret to a flawless final product. It’s what separates an engraving that looks sharp, professional, and full of life from one that ends up looking a bit muddy or lost. Whether you're a company with strict brand guidelines or just someone creating a one-of-a-kind gift, a little prep work goes a seriously long way.

Vector vs. Raster: The Blueprint and the Photograph

First things first, let's talk file types. This is probably the most crucial step in prepping your design for any wood engravings custom project. Think of it this way: you wouldn't use a paintbrush to hammer a nail, right? In the design world, that means picking the right file for the job, and your two main choices are vector and raster.

-

Vector Files (.AI, .SVG, .EPS): Picture a vector file as a set of architectural blueprints. It isn't made of pixels; it's built from pure mathematical equations that define every point, line, and curve. Because it's all math, you can scale a vector logo from the size of a postage stamp to the size of a billboard without losing an ounce of quality. It will stay perfectly crisp and clean, which makes vector the absolute gold standard for logos, text, and sharp graphics.

-

Raster Files (.JPEG, .PNG, .TIFF): Now, think of a raster file as a photograph. It’s a grid of thousands of tiny colored squares called pixels. This format is fantastic for capturing the subtle shading and rich detail of a photo, but there's a catch: raster files have a fixed resolution. If you try to blow up a low-res image, it just gets blurry and pixelated—a recipe for a poor-quality engraving. If you're using a photo, high-resolution is non-negotiable.

For corporate awards, promotional items, or anything with a logo, a vector file is the only way to go. It’s your guarantee that the brand’s identity will be etched with the cleanest lines and sharpest possible finish.

Design Details That Make a Difference

Once you’ve got the right file type sorted, it’s time to zoom in on the details. Just because a design looks amazing on your bright computer screen doesn't mean it will pop on wood. The laser has its own way of interpreting things, and the wood grain itself adds another layer to the equation.

It helps to think of the wood's grain as a subtle, organic pattern that’s already there. Designs with tons of super-fine, whisper-thin lines or tiny, crowded text can easily get swallowed up by this natural texture. The laser can struggle to etch these delicate details, causing them to merge or just disappear into the wood.

Insider Tips for a Flawless Finish

Here are a few quick tips from the workshop floor to make sure your design is laser-ready:

- Beef Up Your Lines: Stay away from ultra-fine lines. A slightly thicker line weight will engrave much more cleanly and create a bolder look against the wood grain.

- Pick Your Fonts Wisely: Simple, clear fonts are your best friends here. Super ornate or delicate script fonts can become a jumbled mess, especially at smaller sizes. Stick with clean sans-serif or bold serif fonts for the best readability.

- Embrace Contrast: Designs with strong positive and negative space (think bold black and white) produce the most dramatic and eye-catching results. Images with too many gray mid-tones can end up looking flat and washed out once engraved.

- Resolution is King: If you absolutely have to use a raster file (like a family photo), make sure it's at least 300 DPI (dots per inch) at the final size you want it engraved. A low-res image will always produce a blurry result.

This focus on detail is what elevates the craft. And it's fascinating to see how this digital precision fits into the broader world of woodworking. The global market for traditional wood carving tools, valued at USD 0.17 billion, is expected to hit USD 0.24 billion by 2033. According to Business Research Insights, this shows that even as technology advances, our appreciation for hands-on artistry is stronger than ever.

The 4ULaserWorks Advantage

Feeling a little lost in a sea of file types and resolutions? That’s what we're here for. At 4ULaserWorks, we don’t just take your file and push a button. As a BBB Accredited business trusted by schools, sports teams, and major companies, we know that expert guidance is a huge part of the process.

Our team will work right alongside you to review and fine-tune your artwork. We can help convert files, suggest tweaks to make your design more engravable, and obsess over every detail before the laser even warms up. This partnership ensures that your final piece—whether it's a custom wood box or a set of personalized drinkware—is something you’ll be absolutely thrilled with.

Inspiring Ideas for Custom Wood Engravings

Alright, so what can you actually make with custom wood engraving? The real answer is… pretty much anything you can dream up. This is where the magic happens, turning a simple piece of wood into something with real meaning, whether you’re making a statement for your business or creating a gift that’ll be cherished for a lifetime.

And people are catching on. The engraving services market is booming, expected to jump from USD 295.38 million in 2025 to a whopping USD 432.67 million by 2030. That explosion shows a massive appetite for unique, personalized items, a trend you can read more about on Research and Markets.

For Business and Corporate Branding

In the business world, a first impression is the only impression. Let's be honest, those generic plastic pens and flimsy notepads usually find a permanent home in a forgotten desk drawer. Custom engraved wood, on the other hand, feels different. It has weight. It feels thoughtful, premium, and permanent.

As a BBB Accredited business, we’ve seen countless corporate clients, from credit unions to major banks, recognize the power of a gift that feels intentional. Here are a few of the most popular ways they put wood engraving to work:

- Sophisticated Corporate Awards: Ditch the generic acrylic trophies. An engraved wood plaque has a classic, prestigious feel that truly honors an employee's hard work.

- Branded Wood Boxes: Perfect for presenting high-end gifts like a nice bottle of wine or premium tech. The box itself becomes a beautiful keepsake long after what's inside is gone.

- Unique Promotional Gifts: Think engraved coasters, charcuterie boards, or even phone stands. They’re practical items that keep your brand front-and-center in a client's daily life.

- Elegant Event Decor: From custom table numbers at a fundraising gala to directional signs at a conference, engraved wood adds a touch of class that instantly elevates the atmosphere.

It's all about turning everyday objects into powerful branding moments. A sharp, beautifully engraved logo is so much more than a mark—it’s a symbol of your company's commitment to quality. We get into the nitty-gritty of making your logo pop in our guide to laser logo engraving.

"A custom engraved item acts as a physical touchpoint for your brand. In a digital world, something tangible and beautifully crafted stands out and creates a lasting connection."

For Personal Gifts and Home Decor

Outside the boardroom, wood engravings custom made for personal moments are where the real heart is. This is how you capture a memory, celebrate a milestone, or just create something beautiful for your own home. The natural warmth of wood brings a personal touch that other materials just can't replicate.

These projects are fueled by creativity and emotion, which is why every single one is completely unique.

Unforgettable Gift Ideas:

- Personalized Cutting Boards: An absolute classic for a reason! They’re the perfect gift for weddings, housewarmings, and anniversaries. Engrave a family name, a special date, or even a treasured family recipe in a loved one's actual handwriting.

- Engraved Family Portraits: Turn a favorite photo into a timeless piece of art. A laser can etch stunningly detailed images onto wood, creating a rustic and beautiful keepsake that will last for generations.

- Custom Keepsake Boxes: The perfect home for wedding photos, old letters, or a baby's first shoes. A box engraved with a child's name and birthdate is a gift new parents will absolutely treasure.

- Unique Home Decor: Imagine a set of wooden coasters etched with a map of your city, a custom welcome sign for your front door, or a piece of wall art featuring your family's favorite quote.

We’ve had the pleasure of creating custom items that build community pride for schools and sports teams, like our officially licensed work with Creighton University. The same idea applies to personal gifts—it’s all about crafting something that tells a story and brings people together. Whether for your business or your home, a custom wood engraving turns an ordinary object into an extraordinary memory.

Caring for Your Custom Wood Engraving

So, you've got a beautiful custom-engraved wood piece. Fantastic! It's not just another item; it's a keepsake, a trophy, or maybe even a piece of art that tells a story. The best part? Keeping it looking brand-new is easier than you think.

Let's get one thing straight: harsh chemicals and abrasive scrubbers are your enemy. They'll strip the finish, dull the wood's natural warmth, and can even mess with the delicate details of the engraving. Your new best friend is a simple, soft microfiber cloth.

The Dos and Don'ts of Cleaning

Most of the time, all your piece needs is a gentle dusting. A quick wipe with a dry, lint-free cloth will keep it from looking tired and collecting grime. It’s a small step that makes a huge difference in preserving that "just engraved" glow.

Got a little smudge or a few fingerprints? No problem. Just barely dampen a clean cloth with a little water—make sure to wring it out well. A gentle wipe should lift it right off. Always, and I mean always, follow up with a dry cloth to make sure no moisture is left behind.

A Word from the Wise: Never, ever spray cleaner or water directly onto the wood. It can seep into the grain and the engraved lines, causing swelling, warping, or even discoloration. Always spray the cloth, not the piece.

Winning the Battle Against the Elements

Wood is alive, in a way. It reacts to its surroundings, so you've got to be mindful of where you display your masterpiece. The two biggest villains are sunlight and moisture.

- The Sun: Think of UV rays as a bleach pen for wood. Too much direct sunlight will fade the color and can make the wood look washed out over time. Find a spot for your piece away from that intense afternoon sun pouring through a window.

- Humidity: Wood expands and contracts with moisture in the air. Big, sudden swings in humidity—like moving it from a dry room to a damp basement—can cause the wood to warp or even crack. A stable, comfortable environment is key.

Follow these simple rules, and your wood engravings custom made for you will look just as incredible years from now as they do today. For pieces that get a lot of handling, like a keepsake box or a serving tray, a little TLC with a wood-safe conditioner or oil now and then can really bring back its shine and protect it for the long haul.

Got Questions About Wood Engraving? We've Got Answers.

Diving into the world of custom wood engraving for the first time? It's totally normal to have a few questions rattling around. From the nitty-gritty tech details to the practical stuff, getting a handle on the basics is key. So, let’s clear up some of the things we get asked about the most.

The first thing on everyone's mind is usually the price. What's this going to cost me? The final price tag depends on a few moving parts: how complex your design is, the size of the final piece, the wood you've picked, and your order quantity. Engraving a simple name on a small box is going to be a lot easier on the wallet than etching a massive, detailed photograph onto a slab of walnut.

Then there's the tech talk about file formats. For logos, text, and other line art, a high-resolution vector file (think .AI or .SVG) is king. It gives us those razor-sharp lines. If a photo is what you're after, you'll want to send over a top-quality image file like a .JPEG or .PNG. Don't sweat it if that sounds like gibberish; we can walk you through getting the right file for the job.

How Tough Is It? And Other Project Details

"So, how long will this engraving actually last?" We get this one all the time, and the answer is my favorite: forever. A laser engraving isn't like ink printed on the surface. We're physically altering the wood itself, so it’s not going to fade, peel, or rub off. It's a permanent mark, creating a true keepsake.

A big one we hear is, "Can I bring in my own thing to be engraved?" More often than not, the answer is yes! But first, we need to take a look. We'll have to check out the material and any finish on it to make sure it's safe to put in our laser and will give you a result you’ll love.

Feeling a bit lost on where to even start looking for a service? We've got you covered. For a much deeper look into finding the perfect fit for your project, check out our guide on https://4ulaserworks.com/blogs/news/where-to-get-stuff-engraved. It's packed with tips to help you find an expert who can nail your vision.